Pneumatic Presses

M250 Benchtop Specimen Die Press

The M250 Specimen Die Press

The M250 Specimen Die Press is optimized for specimen dies and other small die-cutting applications. Ideal for die-cutting tensile and tear physical testing samples in a laboratory, the M250 is also good for general die-cutting of small parts and prototypes.

Specifications

- 6″ x 6″ Work Area

- 2 Tons

- $4,995*

Custom Pneumatic Presses

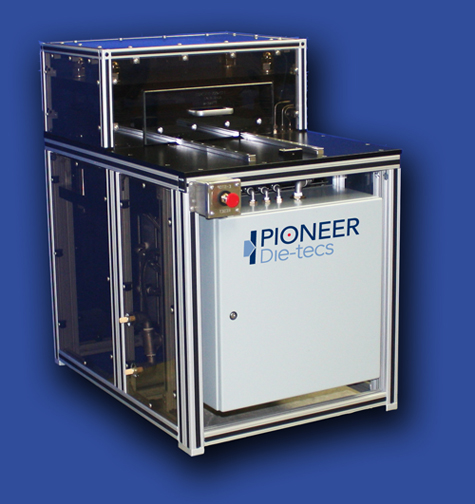

S4000 Semi-Automatic Specimen Die Press

Pioneer manufactures a complete line of custom pneumatic presses with air-logic for semi-automatic cycle of the die ram. Custom-built to your specifications, Pioneer pneumatic presses are all-pneumatic with Pioneer’s proven air-logic system for semi-automatic cycle of the die ram. They are also cost-effective and inexpensive to hook-up with no electricity required.

- CE certification

- Clean room safe

- Die changes in 30 seconds or less

- Micrometer stroke adjust for die-height setting available as an option

- Replaceable nylon or plastic cutting pad included

Press Logic

The Pioneer pneumatic press system configuration:

- Available with 2 to 22 Tons of force

- All pneumatic with air-logic for semi-automatic cycle of the die ram

- Inexpensive to hook-up with no electricity required

- Micrometer die height adjustment available as an option

- Replaceable nylon cutting pad

Safety

The press is in a closed box with multiple safety features and no open areas for fingers or other body parts. The redundant safety devices and lack of “pinch” areas eliminate most safety issues.

Custom Pneumatic Press Models

Pneumatic Cleanroom Press

Custom Benchtop Presses

M250 Benchtop Press

- 6″ x 6″ Work Area

- Available with 1-1/2 Tons of force

- $4,995*

M500 Benchtop Press

- 8″ x 12″ Work Area

- 2-Ton

- $9,995*

M600 Benchtop Press

- Pressure: 6-Ton

- Work Area: 14″ x 14″

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

Free-Standing Custom Presses

M500 Press

- 2 Ton

- 8″ x 12″ Work Area

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

M600 Press

- 6 Ton

- 14″ x 14″ Work Area

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

M1000 Press

- Available in 2, 4 and 6-Ton models

- 12.5″ x 15″ Work Area

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

Semi-Automatic Presses

S500 Press w/Shuttle Table

- 2 Ton

- 8″ x 12″ Work Area

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

S2000 Semi-Automatic Press

- 4 Ton

- 12.5″ x 15″ Work Area

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

- $28,750*

S2500 Semi-Automatic Press

- 10 Ton

- 12.5″ x 15″ Work area

- Suitable for Robotic Integration

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

- $36,500*

S3500 Semi-Automatic Press

- 15 Ton

- 26″ x 26″ Work Area

- Suitable for Robotic Integration

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

- $42,500*

S4000 Semi-Automatic Press

- 20 Ton

- 15 1/2″ x 26″ Work Area

- Suitable for Robotic Integration

- 80/20 Extruded Aluminum Frame

- Moveable/Lockable Wheels

- $52,750*

Pioneer-Dietecs Cleanroom Press

Clean, quiet presses for cleanroom applications

Designed specifically for cleanrooms, Pioneer cleanroom die-cutting presses are all pneumatic and built with our proprietary air-logic system for clean, quiet operation. The Pioneer-Dietecs cleanroom press is suitable for all cleanroom die-cutting applications including medical specimen dies to all ASTM standards.

The cleanroom die-cutting press features a NEMA pneumatics enclosure that’s water-tight, environmentally secure, and sturdy to protect against dust, splashing water, wash-downs, and other contamination. Cleanroom die-cutting presses are available in standard sizes or can be built to any size with custom features available to meet your requirements.

Semi-Automatic Cleanroom Press

Cleanroom Press Design Specifications

- Standard sizes from from 6” x 6” to 24” x 24″ with any size available on request

- Tonnage from 1 ½ to 18 Tons

- Totally pneumatic presses with Pioneer-Dietecs proprietary Air-Logic

- Can be configured for manual or semi-automatic operation

- Cutting surface of stainless steel or FDA approved plastic

- Custom features available to suit specific needs

Pneumatic components enclosed in a waterproof box

- Pneumatic plumbing between components consists of flexible tubing

- Plumbing entering and exiting the cleanroom press is stainless steel tubing, stainless steel clad flexible hose, or equivalent

- Pressure gauges available in stainless steel

- All non-stainless pressure gauges mounted inside the enclosed box

Cleanroom Press hardware is stainless steel, anodized aluminum or powder-coated steel

- Shuttle table handle is stainless steel

- All aluminum components are anodized

All exhaust air connected to an external tank with check valve

The external tank has a pressure gauge attached with two exhaust output ports for venting outside the cleanroom.

Wash-down features available

- Cleanroom press can be equipped to withstand wet processing in the cutting area (i.e. spraying with hydrogen peroxide for sanitizing)

- No through holes on cutting plate

- All tapped holes blind or plugged

- Cutting table linear sliding rail of stainless steel or equivalent

Request a quote for a custom press

To request a quote, send us your work area size requirements and any other specifications for your custom die-cutting press, or call 781-682-7900.

*Press prices are estimates for each press model. To get an actual price based on your specifications, submit a quote request.